Edwin Ernst Menzi (1897-1984) (photo 1) and

The walking excavator Kaiser X4 in 1976 was the first walking excavator of this brand, self-propelled in addition, through hydraulic motors in the rear wheels.

Kaiser S2 4x4 Gator (photos 12) of 10.9 T and 157 hp Perkins engine, designed to work in water and wetlands, has leg elevation at the front wheels. Steering is done either by the front wheels or by the rear wheels or all four wheels. It

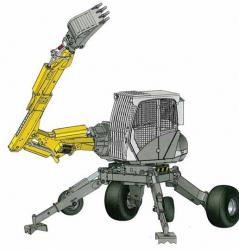

A note about Schaeff, manufacturer of forklift trucks, which began construction of earthmoving equipment including walking excavators (photo 13) in 1994.

2.3 - Released in 2007, the Kaiser S3 Allroad (Photo 14), 11.3 T, 157 hp

The sophistication of the hydraulic system works at pressure of 300 bars at a rate of 190 l / min but the mechanism of translation by a closed circuit produces a pressure of 400 bars at a rate of 140 l / min provided by an axial piston

A61 4x4 Plus of 7.8 T (photo 17) with the same engine has the H-Drive translation system, which increases the efficiency of the transmission of 20%. The automatic level control (optional), which was introduced in 2001 on the A71 (no longer

3.3 - A81 (Fig. 18) of 8.3 T, 120 hp John Deere, is a 4x2 model of reference to

A 111 (photos 21 and 22), 140 hp J. Deere engine for a weight of 12 T is the

Brand of walking excavators Kamo (photo 36) and CRS (photo 37) are found

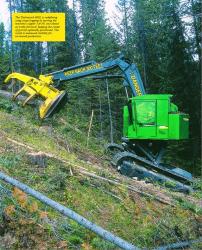

Of course, there has long been special equipment for forest exploitation. They become yet difficult to use in mountains. Of course, there is for a decade more specific forestry equipment such as harvesters Ecolog 4x4, 550C, 16 T for 250

It must still know that the opportunity to work on the slopes is paid, which led some to say that putting more than € 200 000 in the purchase of a walking excavator of 10 T equipped with a grinder is profitable only if it is used only

Computer and hydraulic systems of these excavators are becoming more and more sophisticated and their conduct has a fifty operations so that their control is somewhat related to that of a helicopter. The training of their conduct is very

We see that walking excavators present impressive off-road capabilities on slopes and reasonable rocky grounds. We can at this point ask the question :

Why this failure ? These vehicles probably did not improve that much mobility : you win a few degrees of slope (and

Today (September 2010), only walking excavators and forest harvester, like the Ecolog forest harvester’s type, or the TimberPro tilt cab type seen above are truly designed to move and work in mountains. They are produced in small series.

http://www.viacar.eu/galeria/4/1

- 212 ONE, 2 OR 3 WHEEL VEH 5

- 213 4X4 WHEELED RIG VEH LIG 5

- 214 4X4 WHEELED RIG VEH, MED 5

- 215 4X4 WHEELED RIG VEH, HEA 5

- 216 6x6 WHEELED RIG VEH, LIG 5

- 217 6x6 WHEELED RIG VEH, MED 5

- 218 6x6 WHEELED RIG VEH HEA 5

- 219 8X8 WHEELED RIG VEH, LIG 5

- 220 8x8 WHEELED RIG VEH, MED 5

- 221 8X8 WHEELED RIG VEH, HEA 5

- 222 4X4 WHEELED ART VEH, LIG 5

- 223 4X4 WHEELED ART VEH, MED 5

- 224 4X4 WHEELED ART VEH, HEA 5

- 225 6X6 WHEEL ART VEHI, LIGT 5

- 226 6x6 WHEELED ART VEH, MED 5

- 227 6X6 WHEELED ART VEH, HEA 5

- 228 8x8 WHEELED ART VEH, LIG 5

- 229 8x8 WHEELED ART VEH, MED 5

- 230 8x8 & MO WHE ART VEH, HE 5

- 231 SEMI-TRA & WHE-CUM-TR VE 5

- 232 ONE OR 2 TRA RIG VEH LIG 5

- 233 TWO TRACKS RIG VEH, MED 5

- 234 TWO TRACKS RIG VEH, HEA 5

- 235 FOUR TRACKS RIG VEH, LIG 5

- 236 FOUR TRAC RIG VEH, MED 5

- 237 FOUR TRACKS RIG VEH, HEA 5

- 238 ART TRACKED VEH, LIGHT 5

- 239 ARTICUL TRAC VEH, MEDIUM 5

- 240 ARTIC TRAC VEH, HEAVY 5

- 241 SELF-LEVELING VEHICLES 5

- 242 SCREW VEHICLES 5

- 243 WHEEL ROB AND LUNAR CA 5

- 244 TRACKED AND SNAKE-LIKE ROB

- 245 WALK, HOP, SPH, WSL ROB 5

- 246 SPECIAL OFF-ROAD VEH 5

- 247 TRACKED MOTORCYCLES 5

- 112 ONE, 2 OR 3 WHEEL VEH 4

- 113 4X4 WHEELED RIG VEH LIG 4

- 114 4X4 WHEELED RIG VEH, MED 4

- 115 4X4 WHEELED RIG VEH, HEA 4

- 116 6x6 WHEELED RIG VEH, LIG 4

- 117 6x6 WHEELED RIG VEH, MED 4

- 118 6x6 WHEELED RIG VEH HEA 4

- 119 8X8 WHEELED RIG VEH, LIG 4

- 120 8x8 WHEELED RIG VEH, MED 4

- 121 8X8 WHEELED RIG VEH, HEA 4

- 122 4X4 WHEELED ART VEH, LIG 4

- 123 4X4 WHEELED ART VEH, MED 4

- 124 4X4 WHEELED ART VEH, HEA 4

- 125 6X6 WHEEL ART VEHI, LIGT 4

- 126 6x6 WHEELED ART VEH, MED 4

- 127 6X6 WHEELED ART VEH, HEA 4

- 128 8x8 WHEELED ART VEH, LIG 4

- 129 8x8 WHEELED ART VEH, MED 4

- 130 8x8 & MO WHE ART VEH, HE 4

- 131 SEMI-TRA & WHE-CUM-TR VE 4

- 132 ONE OR 2 TRA RIG VEH LIG 4

- 133 TWO TRACKS RIG VEH, MED 4

- 134 TWO TRACKS RIG VEH, HEA 4

- 135 FOUR TRACKS RIG VEH, LIG 4

- 136 FOUR TRAC RIG VEH, MED 4

- 137 FOUR TRACKS RIG VEH, HEA 4

- 138 ART TRACKED VEH, LIGHT 4

- 139 ARTICUL TRAC VEH, MEDIUM 4

- 140 ARTIC TRAC VEH, HEAVY 4

- 141 SELF-LEVELING VEHICLES 4

- 142 SCREW VEHICLES 4

- 143 WHEEL ROB AND LUNAR CA 4

- 144 TRAC & SNAKE-LIKE ROB 4

- 145 WALK, HOP, SPH, WSL ROB 4

- 146 SPECIAL OFF-ROAD VEH 4

- 147 TRACKED MOTORCYCLES 4

- 76 ONE, 2 OR 3 WHEELED VEH 3

- 77 4X4 WHEELED RIGID VEH, LI 3

- 78 4X4 WHEEL RIGID VEH, MED 3

- 79 4X4 WHEEL RIGID VEH HEAV 3

- 80 6x6 WHEELED RIG VEH, LIG 3

- 81 6x6 WHEELED RIG VEH, MED 3

- 82 6x6 WHEELED RIG VEH, HEA 3

- 83 8X8 WHEELED RIG VEH, LIGH 3

- 84 8x8 WHEELED RIG VEH, MED 3

- 85 8X8 WHEELED RIG VEH, HEA 3

- 86 4X4 WHEELED ART VEH, LIGHT

- 87 4X4 WHEELED ART VEH, MED 3

- 88 4X4 WHEELED ART VEH, HEA 3

- 89 6X6 WHEEL ART VEHI, LIGT 3

- 90 6x6 WHEELED ART VEH, MED 3

- 91 6X6 WHEELED ART VEH, HEA 3

- 92 8x8 WHEELED ART VEH, LIG 3

- 93 8x8 WHEELED ART VEH, MED 3

- 94 8x8 & MO WHE ART VEH, HEA 3

- 95 SEMI-TRA & WHE-CUM-TR VEH 3

- 96 ONE OR 2 TRA RIG VEH LIG 3

- 97 TWO TRACKS RIG VEH, MED 3

- 98 TWO TRACKS RIG VEH, HEA 3

- 99 FOUR TRACKS RIGID VEH, LIG

- 100 FOUR TRACKS RIG VEH, MED

- 101 FOUR TRACKS RIG VEH, HEA 3

- 102 ART TRACKED VEH, LIGHT 3

- 103 ARTICUL TRAC VEH, MEDIUM 3

- 104 ARTIC TRAC VEH, HEAVY 3

- 105 SELF-LEVELING VEHICLES 3

- 106 SCREW VEHICLES 3

- 107 WHEELED ROB AND LUNAR CA

- 108 TRACKED & SNAKE-LIKE ROB

- 109 WALK, HOP, SPHL, WSL ROB

- 110 SPECIAL OFF-ROAD VEH 3

- 111 TRACKED MOTORCYCLES 3

- 39 ONE, 2 OR 3 WHEELED VEH 2

- 40 4X4 WHEELED RIG VEH., LIG 2

- 41 4X4 WHEELED RIG VEH, MED 2

- 42 4X4 WHEELED RIG VEH, HEA 2

- 43 6x6 WHEELED RIG VEH, LIG 2

- 44 6x6 WHEELED RIG VEH, MED 2

- 45 6x6 WHEELED RIG VEH, HEA 2

- 46 8X8 WHEELED RIG VEH, LIGH 2

- 47 8X8 WHEELED RIG VEH, MED 2

- 48 8X8 WHEELED RIG VEH, HEA 2

- 49 4X4 WHEELED ART VEH, LIGHT

- 50 4X4 WHEELED ART VEH, MED 2

- 51 4X4 WHEELED ART VEH, HEA 2

- 52 6X6 WHEEL ART VEHI, LIGT 2

- 53 6x6 WHEELED ART VEH, MED 2

- 54 6X6 WHEELED ART VEH, HEA 2

- 55 8x8 WHEELED ART VEH, LIG 2

- 56 8x8 WHEELED ART VEH, MED 2

- 57 8x8 & MO WHE ART VEH, HEA 2

- 58 SEMI-TRA & WHE-CUM-TR VEH 2

- 59 ONE OR 2 TRA RIG VEH LIG 2

- 60 TWO TRACKS RIG VEH, MED 2

- 61 TWO TRACKS RIG VEH, HEA 2

- 62 FOUR TRACKS RIG VEH, LIG 2

- 63 FOUR TRACKS RIG VEH, MED 2

- 64 FOUR TRACKS RIG VEH, HEA 2

- 65 ART TRACKED VEH, LIGHT, 2

- 66 ARTICUL TRAC VEH, MEDIUM 2

- 67 ARTIC TRAC VEH, HEAVY 2

- 68 SELF-LEVELING VEHICLES 2

- 69 SCREW VEHICLES 2

- 70 WHEELED ROB AND LUNAR CA 2

- 71 TRACKED & SNAKE-LIKE ROB 2

- 72 WALK, HOP, SPHL, WSL ROB &

- 73 SPECIAL OFF-ROAD VEHICLES 2

- 74 TRACKED MOTORCYCLES 2

- 75 ADDITIVE 2.1

- 0 ONE, 2 OR 3 WHEELED VEHICL

- 1 4X4 WHEELED RIGID V, LIGHT

- 2 4x4 WHEELED RIGID V, MEDIU

- 3 4x4 WHEELED RIGID V, HEAVY

- 4 6X6 WHEELED RIGID V, LIGHT

- 5 6X6 WHEELED RIGID V, MEDIUM

- 6 6X6 WHEELED RIGID V, HEAVY

- 7 8X8 WHEELED RIGID V, LIGHT

- 8 8X8 WHEELED RIGID V, MEDIUM

- 9 8X8 A M WHEELED RIGID V, HE

- 10 4X4 WHEELED ARTIC V, LIGHT

- 11 4x4 WHEELED ARTIC V, MEDIU

- 12 4x4 WHEELDED ARTIC V, HEAV

- 13 6X6 WHEELED ARTIC V, LIGHT

- 14 6X6 WHEELED ARTIC V, MEDIUM

- 15 6X6 WHEELED ARTIC V, HEAVY

- 16 8X8 WHEELED ARTIC V, LIGHT

- 17 8X8 WHEELED ARTIC V, MEDIUM

- 18 8X8 WHEELED AND MORE ARTIC

- 19 SEMI-TRACKED & WHEEL-CUM-T

- 20 ONE, 2 OR 3 TRACKED RIG LIG

- 21 TWO TRACKS RIGID V, MEDIUM

- 22 TWO TRACKS RIGID V, HEAVY

- 23 FOUR TRACKS RIGID V, LIGHT

- 24 FOUR TRACKS RIGID V, MEDIUM

- 25 FOUR TRACKS RIGID V, HEAVY

- 26 ARTICULATED TRACKED V, LIGH

- 27 ARTICULATED TRACKED V, MED

- 28 ARTICULATED TRACKED V, HEAV

- 29 SELF-LEVELING VEHICLES

- 30 SCREW VEHICLES AND ROBOTS

- 31 WHEELED ROBOTS AND LUNAR CA

- 32 TRACKED AND SNAKE-LIKE ROBO

- 33 WALKING, HOPPING, SPHERICAL

- 34 SPECIAL OFF-ROAD VEHICLES

- 35 TRACKED MOTORCYCLES & CYCLE

- 36 ADDITIVE 1

- 37 ADDITIVE 2

- 38 ADDITIVE 3

- J.A. BOMBARDIER : SNOW TRAVEL

- ROLLIGONS

- NODWELL, CANADAIR AND FOREMOST

- COURNIL TRACTOR

- MEILI TRACTORS AND GAMA-GOAT

- THIOKOL AND LMC TRACKED VEHICL

- CJSC 'TRANSPORT'

- SPECIAL VEHICLES SPEVEMAT

- DAVID HANSEN, DESIGNER HMV

- DAVID HANSEN, DESIGNER HMV II

- DAVID HANSEN, DESIGNER HMV III

- THE OFF-ROAD SHERP AND THE EXP

- LUSTO M FINLAND : FOREST MACHI

- TOUR OF SPEYER AND SINSHEIM

- VISITS OF MUSEUMS IN MOSELLE

- VISIT OF THE DUFRESNE MUSEUM

- PICTURES OF THE AUTHOR I

- PICTURES OF THE AUTHOR II

- PICTURES OF THE AUTHOR III

- PICTURES OF THE AUTHOR IV

- PICTURES OF THE AUTHOR V

- MUSEUM OF VEHICLES, STRÄNGNÄS,

- FORESTRY MUSEUM OF LYCKSELE, S

- OFF-ROAD VEHICLES OF BURGDORF,

- COLLECTION OF BRUNO TABARE, TR

- FOUNDATION MARIUS BERLIET, LE

- LOCOMOTION FESTIVAL

- EUROFOREST EXHIBITION, St BONN

- MUSEUM OF VEHICLES, SAUMUR, FR

- VEHICLES IN NORMANDY MUSEUMS

- SIMA 2015 PARIS-NORD VILLEPINT

- INTERMAT 2015, PARIS-NORD VILL

- FULL-RUENTHAL SWISS MILITARY M

- AGRICULTURAL AND AUTOMOBILE MU

- CONSERVATORY OF AGRICULTURAL M

- FESTIVAL OF OLD MECHANICS AT

- THE PARK OF TITANS, CARMAUX

- CONTACT SHEETS 1 : LOCOMOTION

- CONTACT SHEETS 2 : EUROFOREST,

- CONTACT SHEETS 3 : INTERMAT

- CONTACT SHEETS 4 : SIMA, INTER

- CONTACT SHEETS 5 : MISCELLANEO

Français

Français

English

English

Español

Español

Italiano

Italiano

Deutsch

Deutsch

Nederlands

Nederlands

Portuguesa

Portuguesa